Avant-garde also for its attention to the environment, so much so that already in 2010 we received another important recognition: the environmental certification pursuant to the UNI EN ISO 14001:2004 standard, then updated to the new edition (2015) in May 2016.

In 2023 the management passed into the hands of the Colombo family, in doing so, excellence in the world of turned brass parts met the excellence of turned steel parts, this operation allowed both companies to strengthen their presence on the market and expand the range of supply for their customers.

Thanks to the use of touch screens and PCs on each machine, OMMES guarantees total traceability of production batches, from the raw material to the finished product, marked with a barcode label. In addition, through the latest generation PLCs, it is able to collect and process all the KPIs related to production in real time.

Despite economic challenges, an ever-changing geopolitical context and the resulting uncertainties, OMMES has continued to invest in new state-of-the-art machinery, staff training and has always used high-quality brass alloys from renowned suppliers such as Gnutti Chiari and ALMAG.

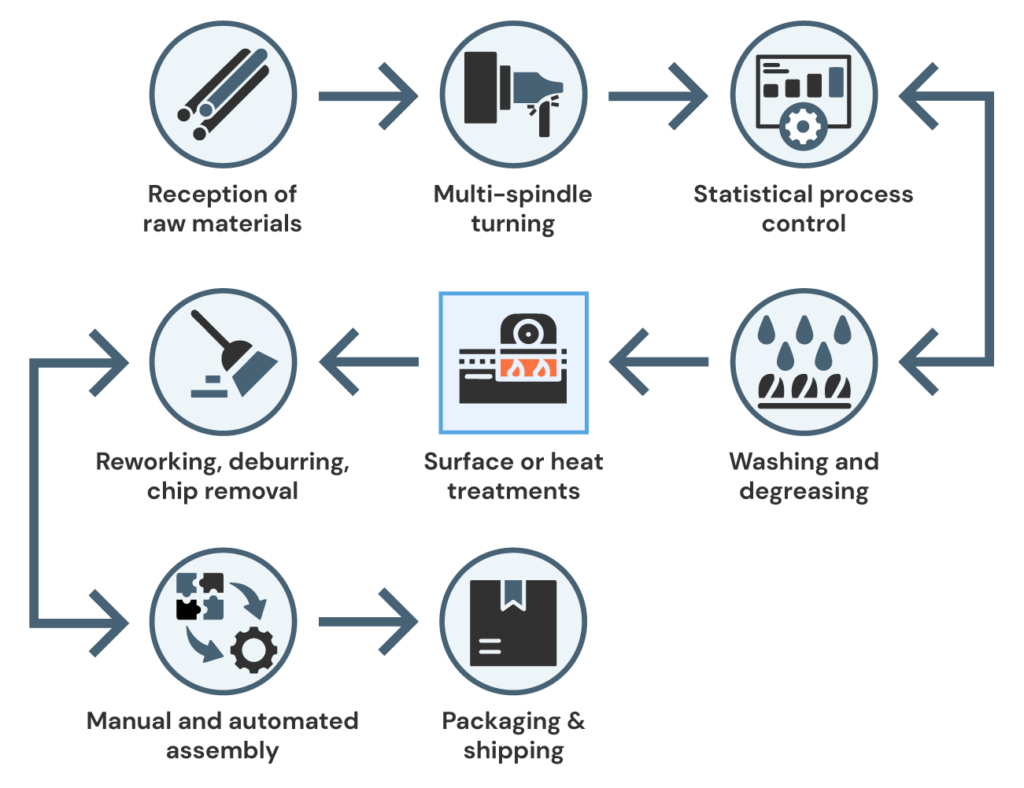

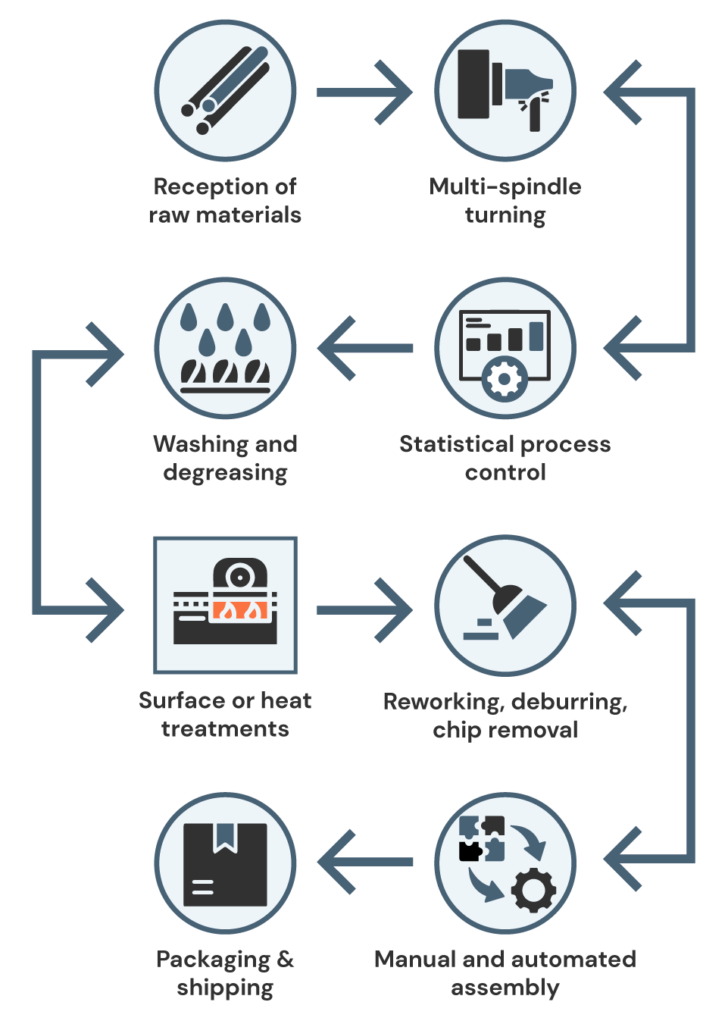

OMMES as a last challenge has chosen to invest in the assembly of its products, creating a new area dedicated to automatic and manual assembly. This new department is equipped with 4 automatic assembly machines, two semi-automatic assembly machines and one bagging machine with automated printer. All this to strengthen its competitiveness on the market, offering added value to its customers.

The company is equipped with 25 SCHÜTTE multi-spindle automatic lathes, customized to meet specific customer needs, with spindles equipped for special machining and much more. All machines are also equipped with PIETRO CUCCHI automatic bar loaders, with bar passage from Ø4mm to Ø70mm. DISCOVER THEM IN DETAIL

Nickel Plating, Chrome Plating, Zinc Plating, Brushing and Diamond Plating

Annealing and Stress Relieving

Precote, Gleitmo, Cataphoresis...

Automatic, semi-automatic or manual assembly

100% control and deburring

Customized packaging and labeling

In addition to punctuality in service and stable costs guaranteed by raw material contracts, we have experience with collaborative Supply Chain methods such as VMI, SMI and Consignment Stock.

All right reserved – Ommes s.r.l | via Medaletto nr.249 23027 Samolaco (SO) –CCIAA, C.F. e P.IVA 00802150144 – Codice REA SO-60745 – Cap.Soc. € 100.000,00